Audit-Ready Pharmacy Inventory Through Physical Verification

December 23, 2025 | By Stockount

Pharmacy inventory audits, which were once conducted once or twice a year, are no longer considered sufficient for compliance. Pharmacies are now under pressure to demonstrate, rather than presume, that inventory records accurately reflect physical stock. This shift is driven by increased regulatory scrutiny, tighter controls on controlled substances, and higher patient safety expectations.

Despite this, many pharmacies still rely on manual registers, system stock, or spreadsheets that are rarely verified on the shelf. Even when systems appear accurate, the primary reason pharmacy inventory audits fail is the gap between records and physical reality.

An audit-ready pharmacy inventory approach emphasizes verification, traceability, and accountability—allowing pharmacies to remain inspection-ready throughout the year rather than scrambling before audits.

Why Inventory Risk Is Higher in Pharmacies Than Other Retail Businesses

Pharmacy inventory management differs significantly from general retail. Medicines are regulated goods, and stock control errors can have serious consequences.

Inventory risk is higher because pharmacies handle:

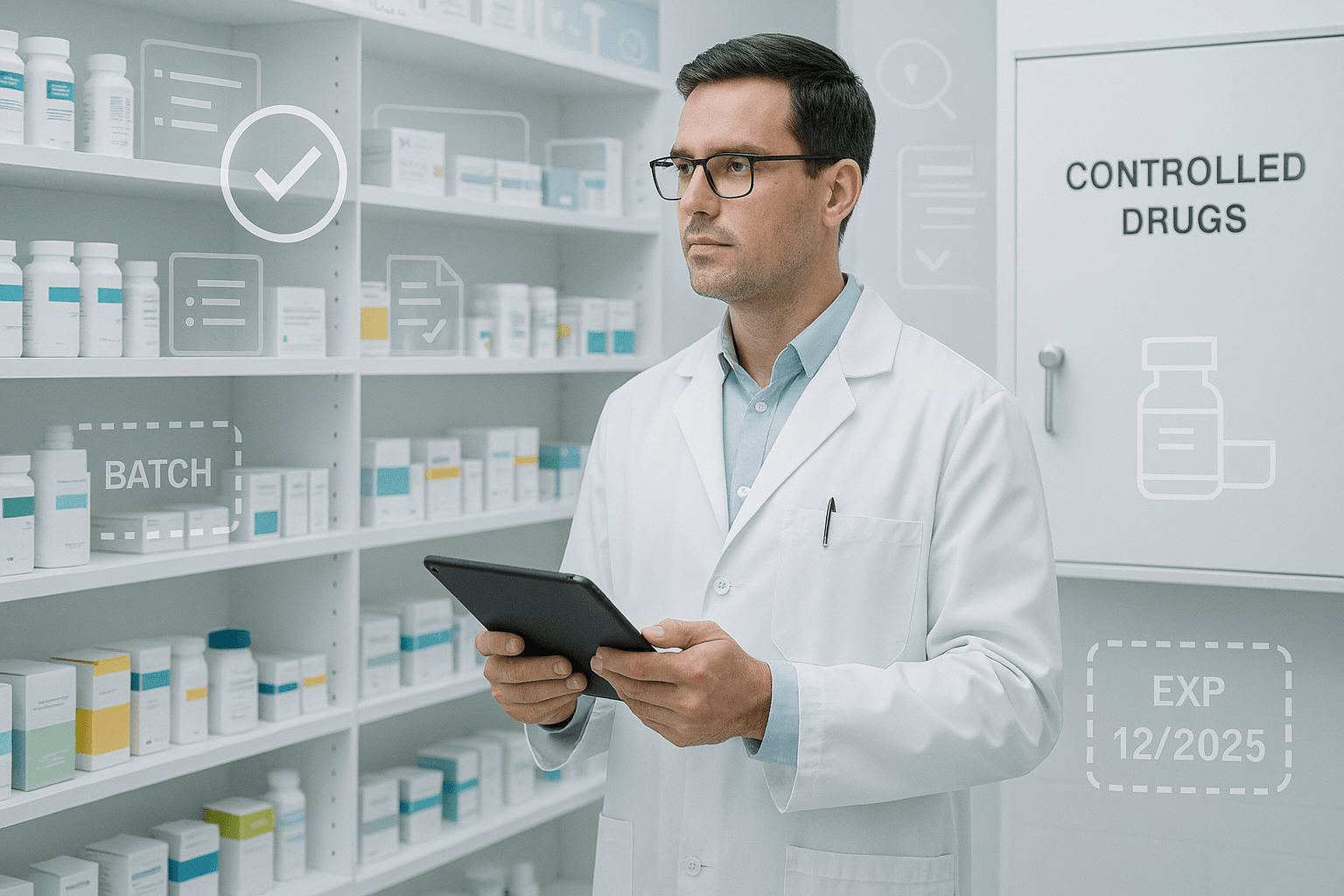

- High-value and high-sensitivity medicines

- Batch-controlled inventory with short expiration cycles

- Scheduled and controlled medications

- Mandatory pharmacy compliance audits

When system stock and physical stock are misaligned, the impact extends beyond margins. It can lead to repeat audits, inspection observations, and mandatory corrective actions. Pharmacy inventory systems must therefore provide verifiable proof of stock existence, not just tracking.

The Real Reason Pharmacy Inventory Audits Fail

Most pharmacy inventory audits fail for one simple reason: inventory is recorded but not validated.

Common issues include:

- Stock movements updated only after dispensing

- Manual registers filled retrospectively

- Advance notice of inspections without recent physical counts

When auditors ask how numbers were verified, pharmacies often lack convincing evidence. Without clear records showing when stock was physically counted, who counted it, and what discrepancies were found, system data becomes difficult to defend.

What Pharmacy Auditors Typically Check During Inspections

Auditors look beyond system reports. They typically verify:

- Physical presence of medicines on shelves and in storage

- Batch numbers and expiry dates against recorded data

- Reconciliation of controlled drug balances

- Evidence of recent physical inventory audits

- Accountability for who performed verification and when

If physical verification records are missing, auditors may raise concerns even when quantities appear correct.

Why System Accuracy Alone Is Not Enough

Modern pharmacy software can generate clean reports, but auditors are not satisfied with reports alone. System stock represents expected quantities, not verified reality.

Inspectors expect:

- Time-stamped verification records

- Reconciliation notes

- Clear audit trails

Inventory management tracks transactions. Inventory auditing confirms existence. Both are essential—but serve different purposes.

Why Manual Stock Registers Fail Under Audit Pressure

Manual registers, especially for controlled drugs, often fail during inspections because:

- They do not prove physical presence at the time of entry

- Entries can be backdated

- Shelf locations are rarely linked

- Accountability depends on individual discipline

When discrepancies arise, it becomes difficult to identify root causes, increasing compliance risk.

What “Audit-Ready Pharmacy Inventory” Really Means

Audit readiness is not about last-minute preparation. It means operating in a way where inspections do not disrupt daily work.

An audit-ready process ensures:

- Regular physical verification

- Clear ownership of counts

- Time-stamped records

- Documented discrepancies and corrective actions

This shifts inventory control from trust-based to proof-based compliance.

Pharmacy Inventory Audit Process: From Verification to Reconciliation

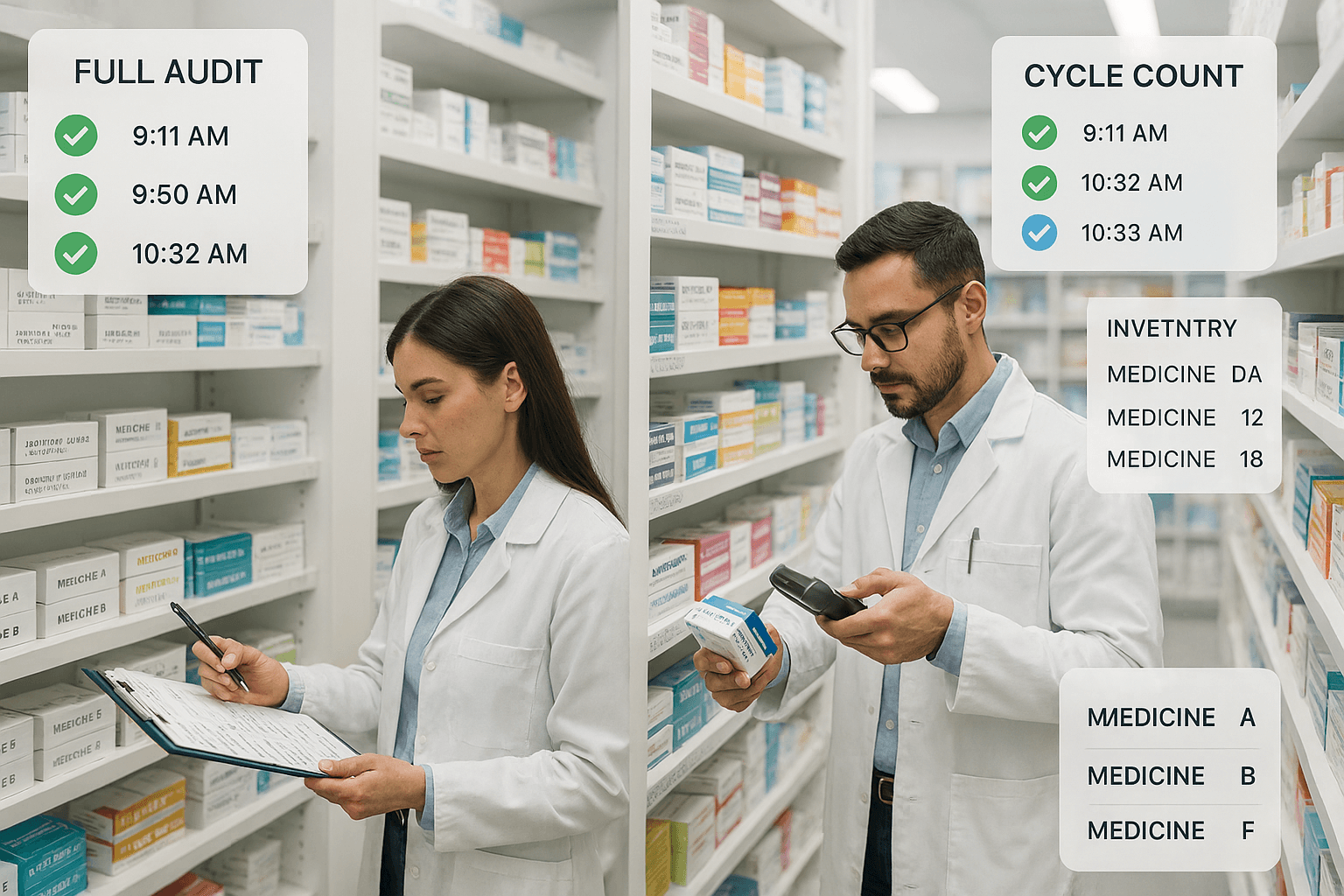

A standard pharmacy inventory audit follows a structured process:

- Review system stock as a baseline

- Conduct physical verification at shelf and storage levels

- Validate batch numbers and expiry dates

- Perform controlled drug audits separately

- Reconcile physical counts with system stock

- Document discrepancies and corrective actions

A pharmacy inventory audit checklist is often used to ensure consistency.

Controlled Drug Inventory Audits: Higher Risk, Higher Expectations

Controlled and scheduled drugs require:

- More frequent verification

- Stricter reconciliation

- Complete traceability

Even small discrepancies can escalate into serious compliance issues if unexplained. Regular audits provide defensible records and early issue detection.

Inventory Audit vs Cycle Counting

- Inventory Audit: Verifies all stock at a specific point in time

- Cycle Counting: Ongoing verification of selected items

Most pharmacies use both. Cycle counting maintains continuous accuracy, while full audits provide comprehensive validation.

How Often Should Pharmacy Inventory Be Audited?

Audit frequency depends on risk:

- Controlled substances: daily or weekly

- Fast-moving medicines: monthly

- Slow-moving or low-risk items: quarterly

Multi-branch pharmacies should also perform cross-location reconciliation.

Handling Stock Shortages, Shrinkage, and Expiry Losses

Common causes of inventory loss include:

- Unverified expiration dates

- Undocumented stock movements

- Rushed counts without accountability

Frequent physical verification identifies issues early, reducing write-offs and audit findings.

Pharmacies with Multiple Branches: Increased Inventory Risk

Inventory risk grows with scale due to:

- Inconsistent counting methods

- Different documentation standards

- Delayed visibility of discrepancies

Standardized audit procedures across branches improve compliance and reduce inspection surprises.

Supporting Modern Pharmacy Audits with Digital Verification

Many pharmacies now use digital tools to:

- Record physical verification

- Preserve audit trails

- Improve traceability

These tools complement ERP and billing systems by ensuring reported quantities are backed by physical proof. Solutions like Stockount help reconcile system stock with shelf reality using time-stamped records.

When Should a Pharmacy Improve Its Inventory Management System?

Consider reviewing inventory practices if you experience:

- Frequent system-to-shelf mismatches

- High expiration write-offs

- Controlled drug discrepancies

- Repeated inspection queries

- Expansion to multiple locations

These issues usually stem from verification gaps, not software defects.

Final Thoughts

Pharmacy audits rebecoming more demanding. Regulators expect accountability, clarity, and proof. An audit-ready inventory approach reduces inspection stress, prevents losses, and protects patient trust.

Continuous physical verification transforms audits from confrontations into confirmations of best practice—allowing pharmacies to operate confidently in an increasingly regulated environment.

FAQ

What is a pharmacy inventory audit?

A pharmacy inventory audit verifies physical stock against system records to ensure accuracy, compliance, and inspection readiness.

How do pharmacy audits work?

They involve physical verification, reconciliation with system stock, documentation of discrepancies, and corrective actions.

Why do pharmacy inventory audits fail?

Most failures result from reliance on unverified system data without physical proof.

How often should pharmacy inventory be audited?

Frequency depends on risk—controlled drugs require frequent checks, while other stock may be audited monthly or quarterly.

Are manual registers sufficient for pharmacy audits?

No. Manual registers alone are insufficient without physical verification and traceable audit documentation.