Inventory Audit for Frozen Foods Stores: Complete Guide

November 19, 2025 | By Stockount

Running a frozen food store can feel like a juggling act between temperature control, expiry dates, product freshness, and customer expectations. There’s a lot going on. And unlike shelf-stable products, frozen foods don’t give you a second chance. A single temperature dip can damage your entire stock overnight.

That’s why a well-planned Inventory Audit for Frozen Foods Stores is essential. It helps you catch issues early, reduce waste, and keep every product, from frozen peas to premium ice creams, safe and sellable.

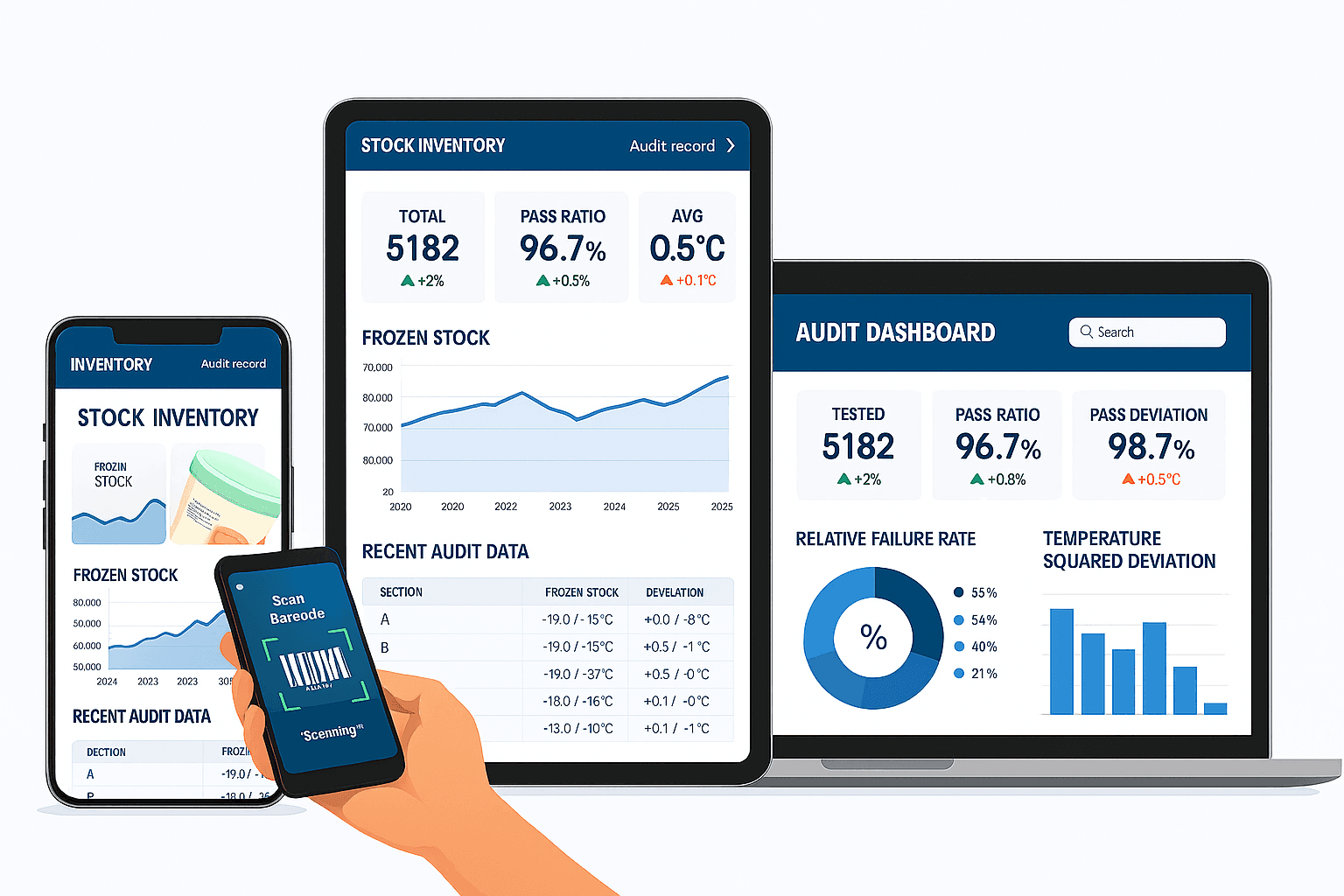

Modern Frozen Food Inventory Software makes it easier than ever by automating temperature logging, expiry tracking, and stock counting.

Why Frozen Food Stores Need Precise Inventory Audits

Frozen foods are sensitive. Their shelf life depends entirely on temperature consistency and proper handling.

Why regular audits matter:

- Avoid losing expensive stock due to thawing

- Maintain hygiene and food safety standards

- Understand real vs. recorded stock levels

- Reduce preventable shrinkage

- Ensure FEFO rotation

- Protect brand reputation

- Improve customer satisfaction

Frozen items have high holding costs. Any error directly affects your bottom line.

Challenges in Frozen Food Inventory Management

Auditing inside a −18°C freezer is difficult and accuracy drops quickly.

Key challenges:

- Temperature changes during audits

- Frost covering barcodes

- Faded or tiny expiry dates

- Melt-refreeze cycles causing hidden shrinkage

- Poor visibility

- Identifying older batches

- Time-sensitive audits

- Handling high-cost SKUs

Role of Frozen Food Inventory Software

Technology simplifies frozen inventory audits by offering:

- Automated temperature logs

- Real-time freezer alerts

- Expiry date tracking

- FEFO rotation assistance

- Accurate barcode scanning

- Mobile audit workflows

- Reduced manual errors

Must-Have Features in Frozen Food Audit Systems

- Digital temperature monitoring

- Cloud-based audit reports

- Expiry alerts

- Batch/lot management

- FEFO automation

- Barcode scan support for frozen labels

- Shrinkage reporting

- Real-time variance detection

Ice Cream Stock Audit: Step-by-Step Guide

Ice cream melts fast and refreezes badly, making audits sensitive.

Steps:

- Check freezer temperature

- Identify soft spots or melted edges

- Inspect lid seals and packaging

- Scan barcodes

- Record thawed or damaged items

- Ensure FEFO rotation

- Verify stacking height

- Check delivery schedules

- Report variances

- Sync findings in the inventory software

Temperature Monitoring Logs

Digital sensors provide:

- Auto temperature recordings every few minutes

- Instant alerts

- Door-open tracking

- Performance graphs

All logs sync automatically—no paperwork needed.

FIFO/FEFO Rotation for Frozen Goods

FEFO (First Expiring, First Out) is essential for frozen goods.

Why FEFO matters:

- Minimizes waste

- Ensures freshness

- Supports food safety

- Reduces complaints

- Improves audit scores

Expiry Date Tracking

Digital expiry tracking allows you to:

- Scan dates during receiving

- Set auto alerts

- Identify near-expiry stock

- Plan FEFO

- Reduce expired stock

High-Cost Frozen Stock Management

Frozen products are expensive due to cold-chain logistics.

To protect profits:

- Monitor stock daily

- Avoid over-purchasing

- Check shrinkage patterns

- Audit high-value SKUs more often

- Validate supplier consistency

Shrinkage & Waste Analysis

Common shrinkage causes:

- Melt-refreeze cycles

- Incorrect stacking

- Damaged packaging

- Missed expiry dates

- Inaccurate receiving counts

Proper audits can reduce waste by 20–40%.

Freezer Compliance Checklist

- Temperature stability

- Door gasket condition

- Proper airflow and spacing

- Frost removal

- Defrost cycle check

- Clean racks

- Clear product labeling

- FEFO arrangement

- Sensor health

- Hygiene practices

Best Practices for Product Freshness

- FEFO scans daily

- Maintain freezers at −18°C or below

- Clean racks regularly

- Train staff on cold-chain handling

- Avoid airflow blockages

- Reduce ice build-up

- Monitor freezer health every shift

How Digital Tools Improve Frozen Food Audits

- Faster barcode scanning

- Real-time temperature insights

- Expiry alerts

- Lower shrinkage

- Mobile audit checklists

- Cloud dashboards

- Accurate variance reports

Final Thought

A strong Inventory Audit for Frozen Foods Stores protects quality, reduces shrinkage, and boosts profit. With modern Frozen Food Inventory Software, you gain full control over expiry, temperature, and stock movement.

Frozen foods are tricky, but with the right tools and consistent audits, operations become smooth, efficient, and profitable.

FAQ

1. Why are frozen food audits important?

They ensure safety, freshness, accuracy, and cost control.

2. How can technology reduce frozen food waste?

Through automated temperature logging, expiry tracking, and FEFO rotation.

3. What makes frozen foods difficult to audit?

Cold temperatures, faded barcodes, and hidden shrinkage.

4. What is FEFO and why is it important?

First Expired, First Out ensures older stock moves out before spoiling.

5. What’s included in an Ice Cream Stock Audit?

Temperature checks, packaging inspection, barcode scanning, and FEFO alignment.

6. Ideal freezer temperature?

Between −18°C and −25°C.