Why is Stock Audit Crucial for Cloud Kitchens?

July 31, 2025 | By Stockount

Cloud kitchens also known as ghost kitchens ditch dine-in dining and serve food exclusively via delivery apps. This lean model slashes costs on furniture, staff, and front-of-house infrastructure. But behind those savings lies a high-stakes challenge: cloud kitchen inventory management. Without walk-ins or managers to flag missing stock or rising waste, everything depends on clean, reliable data. And where data hygiene falters, operational chaos takes hold.

That’s why regular cloud kitchen stock audits aren’t just compliance they’re strategic fuel for growth, profitability, and customer satisfaction. To tackle this, implementing a robust inventory audit system is essential. This system should track stock movement in real time, compare physical counts against digital records, flag anomalies, and generate actionable insights.

Stock Audit = Business Intelligence in Apron Form

Inventory audits for cloud kitchens aren't just about compliance. They’re data-driven decision-making tools that empower smarter operations. Let’s break down the hidden value they bring:

1. Protecting Against Revenue Leakage

If your kitchen uses more oil than you record or your team keeps grabbing extra sauce packets without logging it—you're bleeding revenue invisibly. A stock audit for cloud kitchens detects these quiet losses and highlights mismatches between what you buy and what you actually use.

2. Controlling Food Wastage Before It Gets Costly

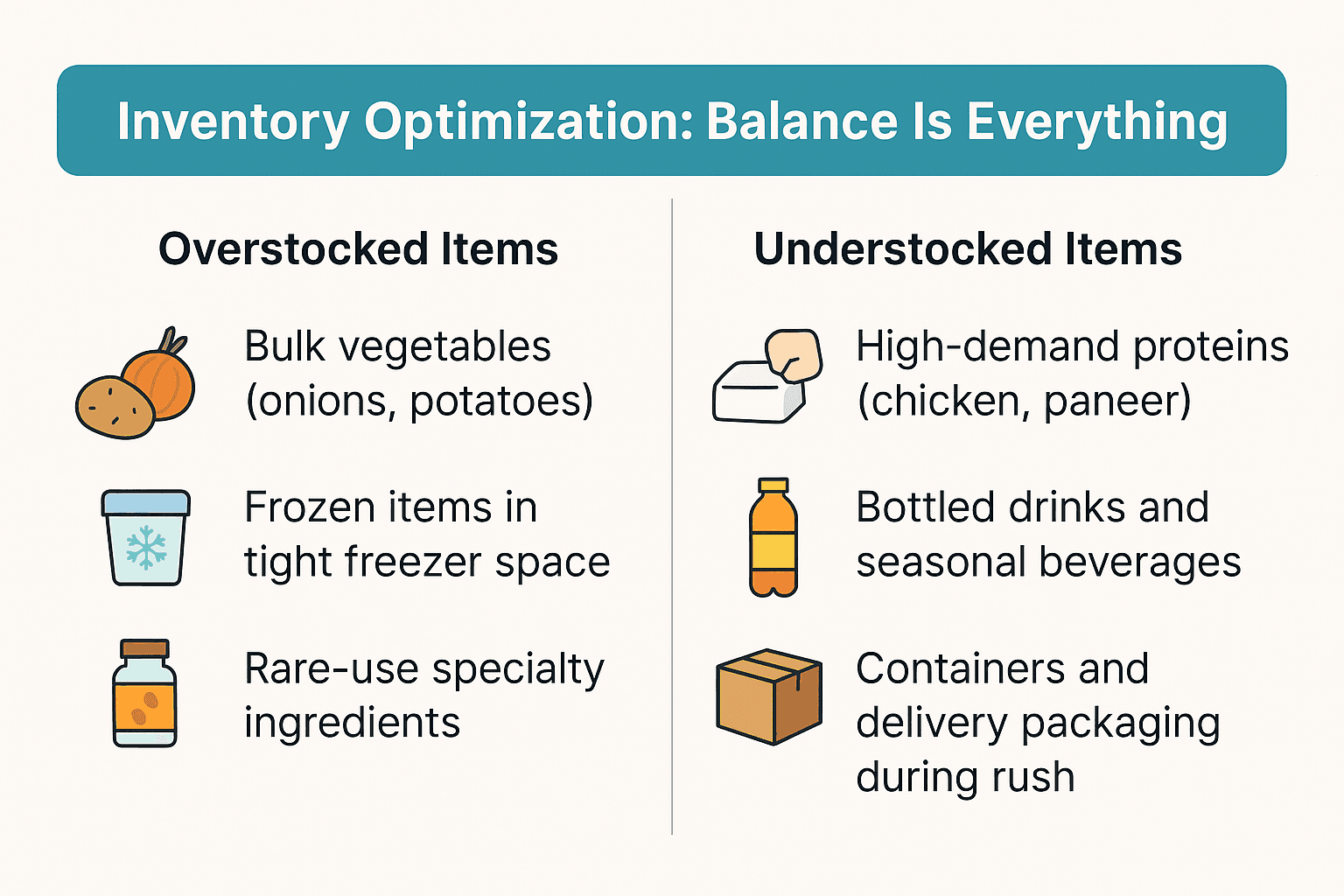

Overestimating demand means overbuying—and for perishables like leafy greens or dairy, it’s a one-way ticket to spoilage. Through auditing, you get visibility into what’s rotting faster than it’s selling. That’s how cloud kitchens avoid tying up capital in forgotten crates of potatoes or freezer-burned chicken tikka.

3. Enhancing Order Fulfillment & Customer Experience

You can’t fulfill orders without stock. When paneer runs dry at 7 p.m., you risk lost sales and disappointed customers. Cloud kitchen inventory tracking software helps forecast demand so you never miss a beat.

4. Reducing Inventory Bloat & Freeing Capital

Let’s talk about the spice drawer: fancy smoked paprika, imported tahini, and saffron bought on a whim for one experimental dish. If these ingredients sit unused for weeks, you’re tying up money and space. A kitchen stock audit checklist can help you decide when to trim the fat.

5. Ensuring Hygiene and Food Safety Compliance

Whether it's adhering to FSSAI or preventing expired stock, compliance audits in cloud kitchens are a must. Batch tracking, expiry monitoring, and FIFO systems build customer trust.

What’s Often Missed in Inventory?

Even advanced systems overlook small details:

Sauces and condiments (used liberally, rarely logged)

Disposables: tissues, cutlery, packaging

Cooking oil and ghee (bulked out, but not monitored per use)

Cleaning agents like dish soap or sanitizers

With Stockount inventory audit software, no consumable goes untracked.

Multi-Brand Complexity: Don’t Let Shared Stock Drain Profits

Running multiple brands from one kitchen? Ingredients like tomatoes or spices often cross menus but without proper SKU attribution, cost leakage is guaranteed. With Stockount’s brand-wise inventory audit s, you can:

Ingredients are mapped to specific brands

Costs are split accurately

Demand forecasting improves per brand

“40% of our tomatoes were logged under a single brand. After switching to Stockount’s tagging, our reconciliation improved by 27%.”

ROI of Audits: Why Frequency Matters More Than Frequency

Cloud kitchen stock reconciliation shouldn’t be occasional—it should be rhythmic.

📌 Get accurate, anytime-anywhere results with weekly cycle count audits for your cloud kitchen using Stockount

Food wastage reduced by 18%

Ingredient availability improved by 25%

Average prep delay cut by 32 seconds

🎯Tip: Regular weekly audits for perishables and high-turn items recover thousands in hidden losses.

Real-Time Tracking & Alerts: Stop Stockouts Before They Happen

While competitors talk visibility, Stockount makes it actionable:

✅ Real-time sync with POS and delivery systems ✅ Smart dashboards by station ✅ Auto-replenishment triggers for fast-moving SKUs

“At 7 p.m., paneer hits critical low? Stockount alerts procurement—your biryani stays on schedule.”

Common Inventory Blindspots

Even advanced systems overlook these items:

Sauces, condiments, and cooking oil

Disposables: tissues, cutlery, boxes

Cleaning supplies: dish soap, sanitizers

Stockount ensures no consumable goes untracked.

Inventory Optimization: Balance Is Everything

Inventory optimization = healthier margins.

Best Practices for Inventory Audits in Cloud Kitchens

Reconcile perishables daily

Conduct category cycle counts weekly

Use RFID/barcodes for accurate tracking

Compare wastage metrics vs. sales trends

Automate audits with Stockount’s dashboard

Final Takeaway: Precision Drives Profit

In cloud kitchens, inventory isn’t just stock it’s strategy. From fixing shrinkage and boosting customer satisfaction to feeding marketing insights, regular cloud kitchen inventory audits are the secret ingredient behind sustainable scaling.

With tools like Stockount, you don’t just record numbers—you translate them into decisions. And in an industry where margins are thin and speed is everything, that’s the kind of leverage that wins.

Cloud Kitchen Inventory Audit: FAQ

Q1. How often should cloud kitchens conduct inventory audits?

A: Ideally, daily for high-turn items like paneer, chicken, and sauces; weekly for broader categories such as packaging or frozen stock. Monthly audits help validate supplier reliability, seasonal usage patterns, and overall kitchen efficiency.

Q2. How do we track shared ingredients across multiple brands?

A: Without SKU-level attribution, ingredients like onions or oil used across brands can distort costing and reporting. Stockount tags shared stock per brand, ensuring transparent allocation, clean profit margins, and accurate usage.multi-brand inventory management ingredient attribution, cost reconciliation

Q3. Why does our kitchen run out of key items during peak hours?

A: Often due to lack of real-time visibility and inaccurate forecasting. Stockount provides consumption heatmaps, predictive reorder triggers, and stock alerts so your inventory matches kitchen rhythm—especially during order surges. real-time inventory tracking, stock alerts demand forecasting, peak hour stockouts

Q4. How does an inventory audit system help reduce food costs?

A: To monitor food usage and purchasing patterns. This helps spot overstocking, underused ingredients, and unnecessary spending.

Q5. What’s ‘silent shrinkage’ and how does the system tackle it?

A: It refers to missing items like oils or sauces due to theft, mismanagement, or unnoticed spoilage. The system highlights these gaps so corrective action can be taken.